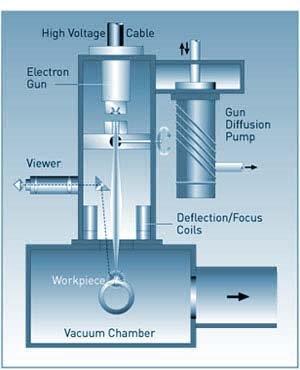

Electron Beam Welding (EBW) is one of several methods used to weld metal components together. It differs from other processes in several important ways, which will be explained in this article. EBW has unique abilities for welding dissimilar metals, complex or curved components and precision parts. Advantages The main advantages of electron beam welding are: High weld strength Fast cycle time Little to no distortion Consistent weld quality Small heat

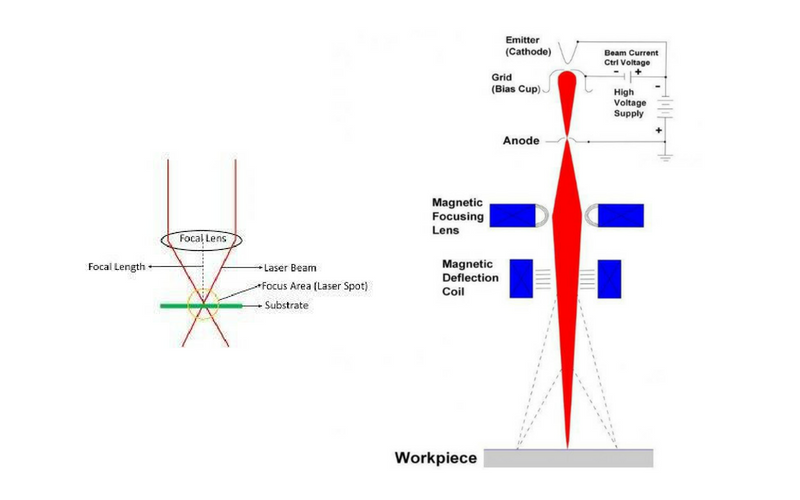

Electron Beam Welding (EBW) and Laser Beam Welding (LBW) and are both fusion welding techniques that use a high energy density beam to melt the joint of two components. Both methods have fast cycle times and produce high weld quality. They are similar and can be used side-by-side in some circumstances, but they are not identical. What Is Laser Welding? Laser Beam Welding uses a concentrated beam of light to

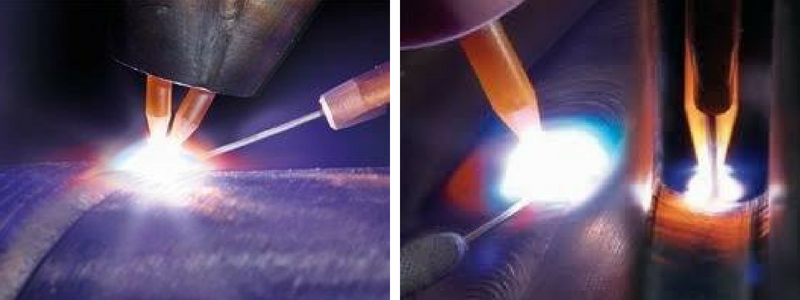

TIG is part of our welding solutions offering and is often complementary to EB Welding. We are a welding specialist committed to the highest weld quality – meeting the needs of complex projects in the aerospace, defence, nuclear, medical equipment, and with approvals from the most demanding OEMs. In-house we have X-ray, Penetrant, Vacuum leak and Pressure testing plus a material section and test laboratory. Our accredited staff and a

Digital Film for Radiography, investment in equipment and training by EBP has now resulted in approval for from Rolls-Royce plc for this process.

EBP approved for precision machining, EB & TIG welding, X-ray and NDT from RRMP

Posted by Peter Vincent

After a lengthy period of assessment EBP are pleased to announce that they have received approval for Precision machining, EB & TIG welding and X-ray and NDT from RRMP. This is the company that supplies both current and future power plants for our submarine fleet, and is further evidence of the quality systems and reputation of EBP

EBP has added SolidCAM and I.Machining to its three SolidWorks seats. This provides integrated 5 –axis machining from CAD input. The patented I.Machining software delivers optimal metal removal rates resulting in shorter cycle times and extended cutter life. Visit www.solidsolutions.co.uk/solidworks/manufacturing/solidcam For more information contact Ian Crook (01483 215404) or Adrian Pragnell (01483 215400, M 07812 588934)

Our Head of NDT, Matt Penfold, has gained Level 3 accreditation for X-ray and Penetrant Inspection, making us independent of external delays and costs in process approval.

EBP has invested £300k in a new 5-axis machining centre with integrated parts loader. The Matsuura MX-520 is due to be commissioned in Jan 2016 and takes EBP into both a new area of complexity and 24/7 operating.

EBP expands with the assistance from the Advanced Manufacturing Supply Chain Initiative (AMSCI)

Posted by Peter Vincent

05/11/2015: £330,000 of funding provided over 2-3 years. EBP expands with the assistance from the Advanced Manufacturing Supply Chain Initiative (AMSCI), who are providing £330,000 of funding over 2-3 years The two key areas of business development are the upgrade of our old generation EB welding equipment to meet the current new build requirements of ISO14744 and to roll this out to other users. We have proved our capability on

EBP have received approval from Rolls-Royce Deutschland for a wide range of services including EB & TIG welding X-ray and FPI, and precision machining.