Design for Manufacturing (DFM) is the process of designing parts, components or products for ease of manufacturing with an end goal of making a better product at a lower cost. This is done by simplifying, optimizing, and refining the product design. We work WITH you not FOR you.

With over 50% of unnecessary manufacturing costs occurring at the design stage, we are dedicated to ensuring your parts are produced efficiently, cost-effectively, and to the highest quality right from the start

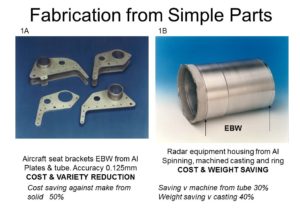

The best applications of EB welding come from design stage discussions with customers. Our free “Best Practice Guide” covers materials, joint designs, and quality control. We offer a DFM service beyond this.

Making the components we assemble and EB weld gives us an understanding of the cost of tough metals with tight tolerances. Our top quality machines and expert CAD/CAM team will take your parts through the full manufacturing lifecycle, from prototype to production at volume

We always comment on the suitability of materials and joint design on enquiries. However, we often find designers do not understand the cost impact of machining features and tolerances. We work with you to understand product function and performance and then minimise the cost drivers to reduce end cost.

This is chargeable as a fix or rolling charge as a Non-Recurring Cost (NCR) or amortised over an agreed period or product quantity.