EB Welding and Additive Manufacturing (AM)/3D Printing

AM can be used to create unique design features in high-strength materials impossible with legacy methods. The AM process for complex parts is slow and expensive, however, the unique design features are often localised.

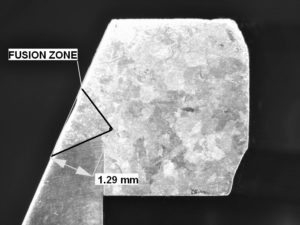

EB Welding can be used to join AM components to conventionally manufactured parts to achieve a more cost-effective final assembly.

Some AM components contain un-fused powder which must be removed. Apertures for powder removal can be sealed with minimal distortion using EBW.