Design for Manufacture (DFM) is the process of minimising product cost by examining designs for ease of manufacture. This is done by reviewing materials, product features and tolerances to eliminate cost drivers, without compromising product integrity. At all times the OEM or Design Authority has ultimate control. DFM is about meeting market demand through a combination of design knowledge and manufacturing expertise to achieve the best value for money.

Design for Manufacture (DFM) is the process of minimising product cost by examining designs for ease of manufacture. This is done by reviewing materials, product features and tolerances to eliminate cost drivers, without compromising product integrity. At all times the OEM or Design Authority has ultimate control. DFM is about meeting market demand through a combination of design knowledge and manufacturing expertise to achieve the best value for money.

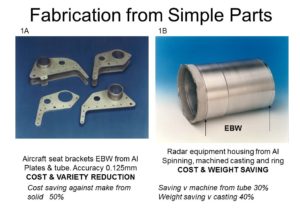

Design Advice for EB Welding, download our Best Practice Guide for free. This contains information on suitable materials, joint design and manufacturing tolerances. We offer in-house training including videos, samples and case studies based on over 50 years’ experience.