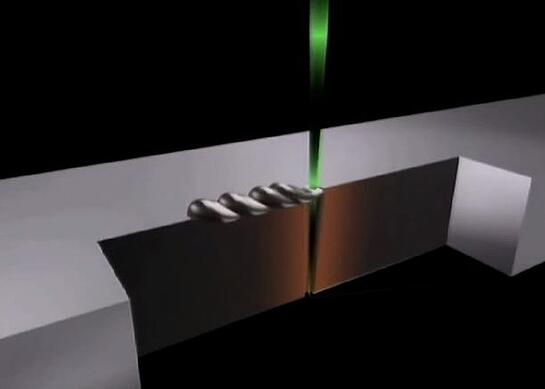

Put very simply, electron beam welding (EBW) is a process whereby two metals are fused or welded together using a beam of high-velocity electrons. This type of welding is suited to applications requiring high-precision, very good repeatability and high-strength.

Electron beam welding is carried out in a vacuum atmosphere to ensure that the beam of electrons are consistently in a stable condition and thus preventing any dispersion before they reach their target – the work piece.

Key Differences Between EBW & Arc Welding

In traditional welding methods such as arc welding heat is generated using a strong electric current which passes through a consumable cathode. This method is very resource intensive and not suited when precision welding is needed and/or sensitive metals are used.

The extreme heat generated by the arc welding process can cause the metal to distort and bend out of shape. By contrast, electron beam welding creates just enough heat in a very localised area to fuse the two metals together across the join. The level of precision that can be achieved with this welding technique is unrivalled.

There is also a significant difference in the complexity and cost of the machinery used in EBW. When asking what EBW is, it is important to understand the differences in machinery required to perform electron beam welding.

Electron beam welders operate under vacuum conditions and because of that they are not portable and can only be used in one static location. Arc welders are portable and can be used out in the field or on a production line. Electron beam welding machines are often used for welding in the aerospace industry or other highly technical applications.

The Cost of Electron Beam Welding

Due of its complexity, electron beam welding is deemed to be more expensive than other forms of welding and is generally only performed by specialist engineering companies.

Arc welding is much less expensive and is the direct welding method of choice when it comes to cost. The high level of precision that EBW can achieve is one of the reasons why it is widely used despite its higher cost. The biggest cost involved in EBW is the initial capital outlay to purchase the required machinery. For this reason most companies outsource their EBW needs unless they use this type of welding on a regular basis.

The total cost of ownership related to EB welding equipment is a consideration which needs to be thought through carefully. The cost of purchase is not the only factor that needs to be taken into consideration, there is also the associated costs of training operators; this can be a long drawn out process because this type of welding is deemed to be very knowledge biased.

Access The Benefits Of Electron Beam Welding

Our company specialises in electron beam welding at what we deem competitive prices. We have over 50 years of experience welding applications which require a high level of technical expertise, putting us at the forefront of electron beam welding technology. In addition to this, we also offer several other services that complement our EB weld offering.

EBP Ltd are industrial members of TWI – The Welding Institute – where we have a huge amount of technical knowledge, advice, support and assistance ready to share with you and subsequently ensure that your needs can be catered for.

Please get in touch to find out more.

![]()